Examples

Practical examples

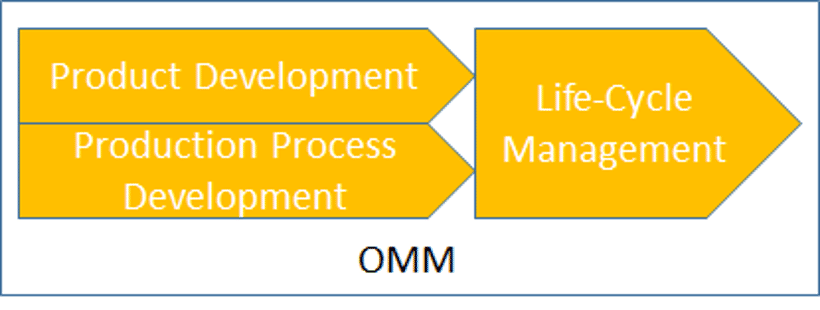

Are you curious about what this looks like in practice? Time for some examples from practice. A brief description is given of the OEM and the supplier. Then the OMM question is described, and finally the most important ’tops and tips’: what went well and what can be learned?

Case study 1

The OEM develops equipment for the semiconductor market. The supplier develops, produces and assembles electronic systems and modules.

For the OEM, a number of electronic modules in its equipment do not contain a core competency. The supplier is willing and able to develop and produce those modules.

The supplier invests in development and recovers the costs through module sales. The OEM is unburdened in this way.

Case study 2

The OEM develops and sells packaging machines. The supplier develops, manufactures and assembles inkjet printer modules.

The OEM needs inkjet printer technology, but has no competence to develop it itself. The supplier has standard printer modules which, via customization, can be built into the packaging machines. The supplier invests in the development and recovers these costs through selling the module. In this way the OEM is unburdened.

What about your business?

Consider the following questions:

- Does the OMM business model fit your company?

- Why does or doesn’t this model fit?

- What are some possible areas of concern for your company with this model?

Does this model possibly fit your organization and would you like to learn more about it?

Then go to ‘Module 9 – Getting started’.