Strategic choices

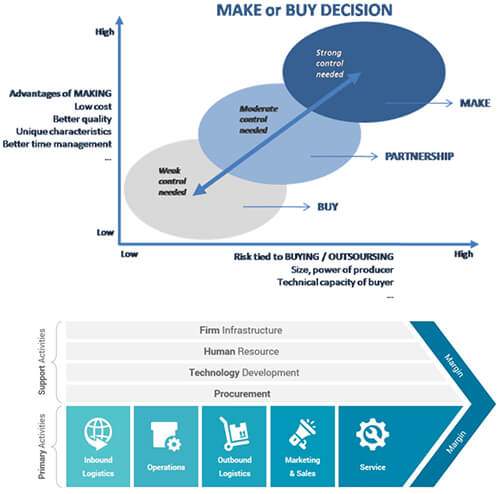

Do it yourself or outsource to third parties?

As a company you have to ask yourself which activities you should (or want to) do yourself and what you can outsource to other companies (suppliers, clients, specialized partners).

Thinking about “make or buy” dates back to the 1970s and is important at strategic, tactical and operational levels. At the strategic level, it is important to determine what the core activities of the company are, now and in the future. Strategic collaboration is aimed at making the best use of knowledge, skills and facilities from outside the organization for internal purposes.

Open innovation exceeds this by starting with defining shared goals and discovering values of “internal resources” for parties outside the organization

Key activities, resources and partnerships

One of the popular business modeling tools is the Business Model Canvas (see image below). Based on the company’s value proposition (“in what way are you valuable to customers?”) you need to make choices about:

- Key activities (“what do you need to do to achieve this?”).

- Key resources (“what resources are needed for this?”).

- Key partners (“who do you need to do this?”).

Collaboration with external partners is necessary to have access to and use knowledge, skills and facilities that are NOT available and/or economically viable within your own company.

Porter’s value chain model

When an activity is crucial to the aforementioned value proposition, the obvious choice is to organize it in-house and invest in knowledge, skills and facilities. This applies both to primary activities such as purchasing, logistics, production, marketing & sales and after sales service and to supporting and condition-creating activities (see Porter’s value chain model). In order not to be completely at the mercy of the market, a company can also opt for an ‘in-between’ solution by developing a partnership with a specialized company and making proper arrangements for cooperation.

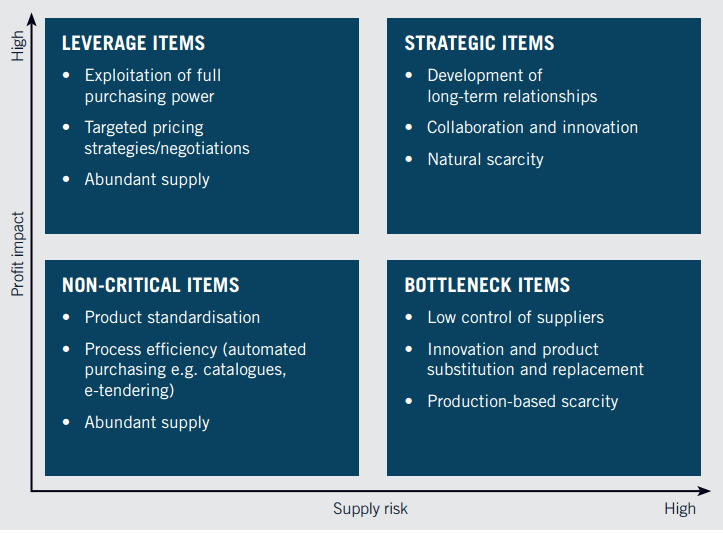

Strategic purchasing

Products, components and services that are not part of the core business of the company will have to be purchased externally. This does not mean that the same approach should be used for all these procurement products (or services).

A widely used tool for determining the procurement strategy is Kraljic’s matrix. Depending on the supply risk (e.g. are there multiple suppliers available?) and the financial interest or risk (how much money is involved) a company can use different strategies (see figure)

Level of subcontracting; buy and make parts

Parts, products or services that are not standard available on the market will need to be developed and made to specification. In subsequent sections M4-M8 of this online course, you will find the strategies a company can use for this purpose.

Did you know that an outsourcer can choose to develop the specific part or module entirely in-house? He can dictate suppliers what the technical specifications are the product and/or manufacturing process must meet.

Another strategy is one in which the supplier is given (much) more freedom to determine – on the basis of functional specifications – what the product or module should look like and how it will be produced.

When to use external resources instead of internal ones?

When an activity is crucial to realize the aforementioned value proposition, the obvious choice is to organize it in-house and invest in knowledge, skills and facilities.